Our competence

The company has expertise and 30-year experience in the development of gas storage pipeline facilities and (including the supporting infrastructure) at all the stages of the project delivery process, i.e. planning, preparation, design, construction and commissioning. Our employees hold a broad range of licences, including those required for the operation of a mining plant.

Source: GK PGNiG Source: GK PGNiG |

Source: GK PGNiG Source: GK PGNiG |

Mining Entity

Underground storage in the subsurface is regulated by the provisions of the Geological and Mining Law, which means that a licence is required in order to carry out business activity in this regard. In 1994, INVESTGAS S.A. established a Mining Plant for the purposes of developing a cavern underground gas storage facility in Mogilno.

The Mining Entity is defined as a technically and organisationally separated set of resources used serving directly for the production of a mineral from a deposit, and operated under the management and supervision of individuals holding adequate licences and qualifications.

The operation of the Mining Entity takes place on the basis of an operations plan, in accordance with the principles of mining engineering.

Licensed specialists

The company's potential builds on the knowledge and experience of its engineering staff. Their extensive practical experience from the implementation of numerous gas, geology and mining projects are our strongest asset. The employees' competence is confirmed with national and international industry certifications related to:- brine extraction through wells,

- mining geology and mining,

- inspection and supervision of geological and mining works,

- design and documentation of geological and mining works,

- servicing and maintenance of electric and pressurized equipment, supervision of CUGS operations,

- European Welding Engineer's qualification recognised by the European Federation for Welding, Joining and Cutting (EWF),

- international tendering and project execution procedures according to the practices of FIDIC, the World Bank and the European Bank for Reconstruction and Development.

Cavern gas storage projects

Business Profile

Our engineering units offer a comprehensive range of services with respect to the development, construction and operation of underground storage facilities for natural gas and other fuels in salt formations or depleted salt mines.

This is an end-to-end service comprising the following stages of the investment cycle:

- preliminary studies and concept definition,

- appraisal of salt deposit suitability for the development of an underground gas storage (UGS) facility,

- feasibility study of UGS development in the appraised salt deposit,

- obtaining the licence for underground gas storage in the subsurface,

- engineering design of the underground part of the UGS facility,

- engineering design of the surface part of the UGS facility,

- supervision over the construction of surface and underground facilities,

- technical and economic evaluation of the UGS construction,

- construction of the UGS facility,

- operation of the UGS facility.

We also offer a comprehensive range of geological services aimed at deposit appraisal and documentation including, inter alia, core logging, drafting of geological maps and sections, 3D geological modelling, estimation of reservoir reserves, identification of reservoir plays suitable for the development of mining plants. We specialise particularly in the appraisal of salt deposits for the purposes of underground storage development.

Preparatory Works

Investment preparation

Our specialists have long-standing experience in the implementation of investment projects and thorough understanding of the operating environment in Poland (and elsewhere). The key elements of the investment preparation process include the following:

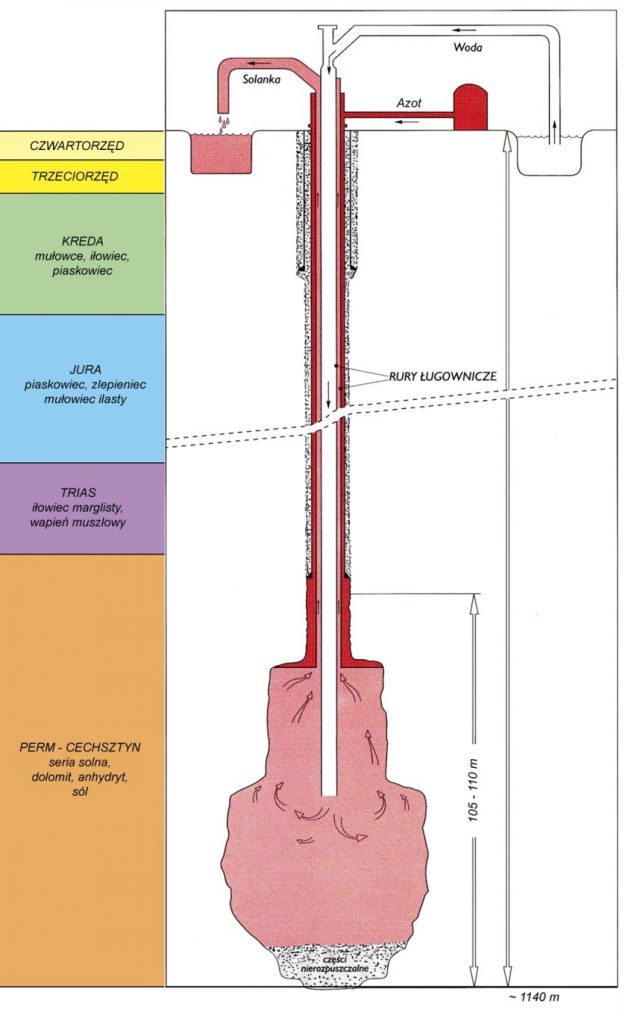

Salt cavern schematic

Salt cavern schematicSource: GSP

- definition of project object and purpose,

- definition of alternative location options,

- scouting visits to confirm the technical feasibility of project location,

- preliminary consultations in order to assess location possibilities within the selected area together with risk assessment taking particularly into account environmental, formal and legal, ownership and technology considerations,

- selection of project location option,

- geological surveys, preparation and approval of geological, geo-engineering and hydrogeological documentation; archaeological surveys and documentation,

- execution of a mining usufruct agreement,

- obtaining a licence (defines the material scope, validity term, surface of the storage area),

- execution of design maps,

- subdivision surveys,

- engineering design documentation (building permit and detailed design) and related consultations with relevant authorities and bodies

- formal and legal procedures in the process of project preparation:

- inclusion of the project in local land use guidelines,

- incorporation of the project in the local development plan of the municipality, or, in case when the local plan is not in place,

- establishing the location for a public purpose project by way of an administrative decision,

- preparation of the Environmental Impact Assessment report and obtaining environmental decisions,

- compensation assessments,

- negotiations concerning the amount of compensation or land purchase price,

- acquisition of the title to land through the execution of civil law agreements with landowners and users with respect to the sites where the project is to be located (in case when temporary access to land is required for project purposes),

- purchase of the plots of land where the project is to be located (in case when permanent land occupation is required for project purposes);

- obtaining the building permit,

- investor's supervision over project execution,

- obtaining the occupancy permit for the project (after completion of the construction).

We undertake diverse research and concept work leading to the completion of specialist studies, such as:

- UGS location studies,

- water sourcing and brine disposal study,

- environmental impact assessment reports,

- UGS development concepts.

We handle formal and legal procedures necessary to undertake project implementation, such as:

- incorporation to the local development plan,

- securing access to land,

- any other activities necessary to undertake works.

Formal and legal documentation

- initial investment assumptions,

- licence,

- feasibility study: project definition and characteristics, feasibility, financial, economic and risk analyses,

- formal and legal documents related to the introduction to the local development plan,

- approval of the engineering and process documentation, building permit design, issuance of the building permit.

Technical and operational documentation

- deposit development plan,

- geological documentation,

- operations plan,

- technical design executions,

- manuals.

Source: GSP

Source: GSP

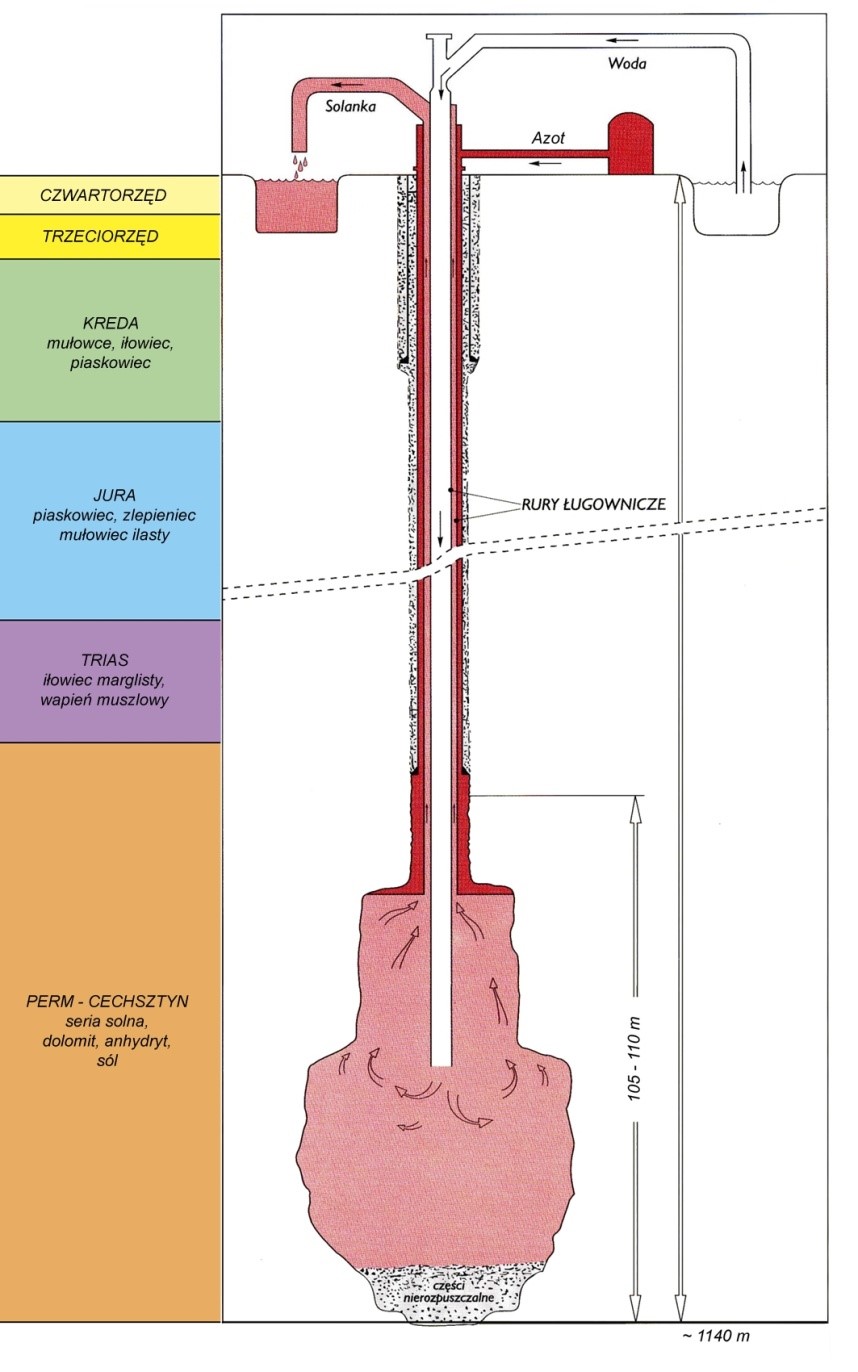

Subsurface Works

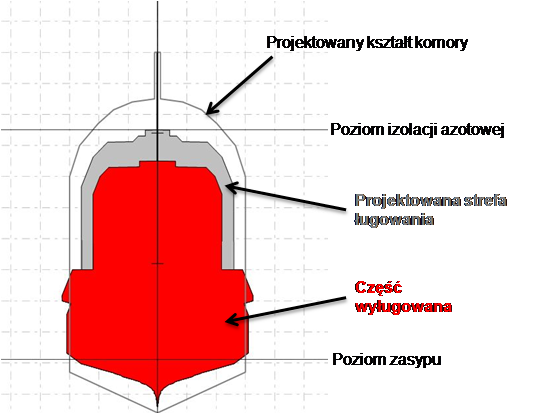

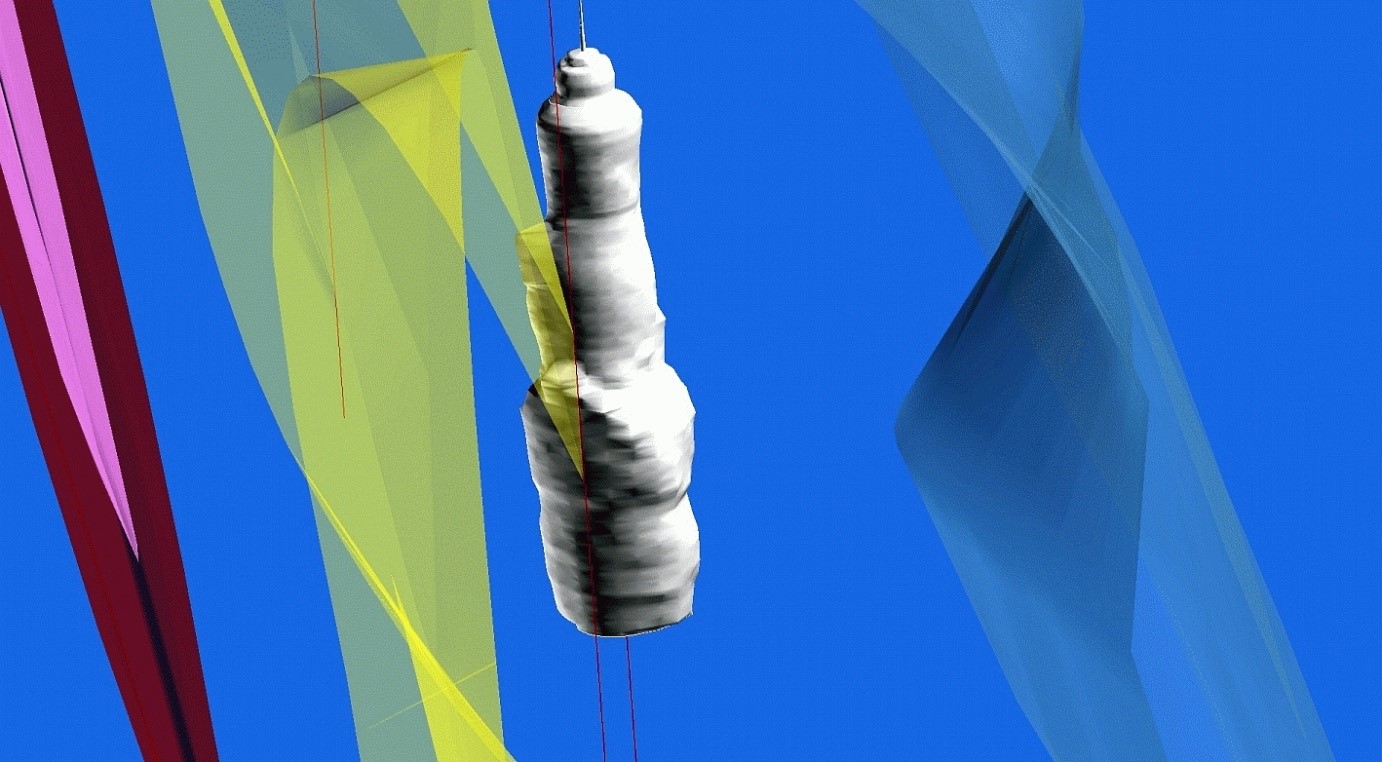

We design all the facility parameters including floor depth, geometry and storage pressures for individual caverns. During the construction of the subsurface part our qualified crews carry out solution mining process in order to ensure optimised construction times and parameters of storage caverns. Once the caverns and surface gas infrastructure are completed, our specialists proceed with an integrated tightness test of the storage cavern, followed by the first gas filling. They also supervise the snubbing of the brine tubing column and overall operation of the UGS facility.

Construction of a storage cavernThe works we supervise: Source: GSP

Source: GSP

- well drilling to the depth of approx. 1600 m,

- running and cementation of production tubing to the depth of approx. 30 m above the planned cavern top,

- running two concentric columns of solution mining pipes,

- well head installation,

- periodical measurements of the cavern geometry and volume by the means of an echo sounder,

- christmas tree installation,

- snubbing,

- installation of downhole safety valve.

Our in-house capabilities include:

- caverns leaching – operation of the installation for water injection to the well and brine flushing

- cavern tightness tests (hydraulic, pneumatic),

- first gas filling.

Geology and engineering

We deliver designs and documentation in the following areas: geology, hydrogeology, geo-engineering and reservoir engineering, as well as deposit development plans, which are required for obtaining a licence for the storage of substances in the subsurface.

With respect to underground CUGS installations, we offer the following engineering design capabilities:- engineering of solution mining wells including the design of tests and geophysical surveys,

- technical design and process engineering of solution mining works (to ensure the planned geometry and volume of storage caverns),

- engineering of cavern tightness tests following the leaching process,

- engineering of the process of first gas filling simultaneous with brine extraction,

- engineering of brine pipe snubbing following the first gas filling.

- programmes of laboratory tests of core samples (geo-mechanics, rheology, suitability for solution mining, mineralogy, chemical properties),

- design of cavern floor depth, geometry and minimum and maximum pressure of stored gas.

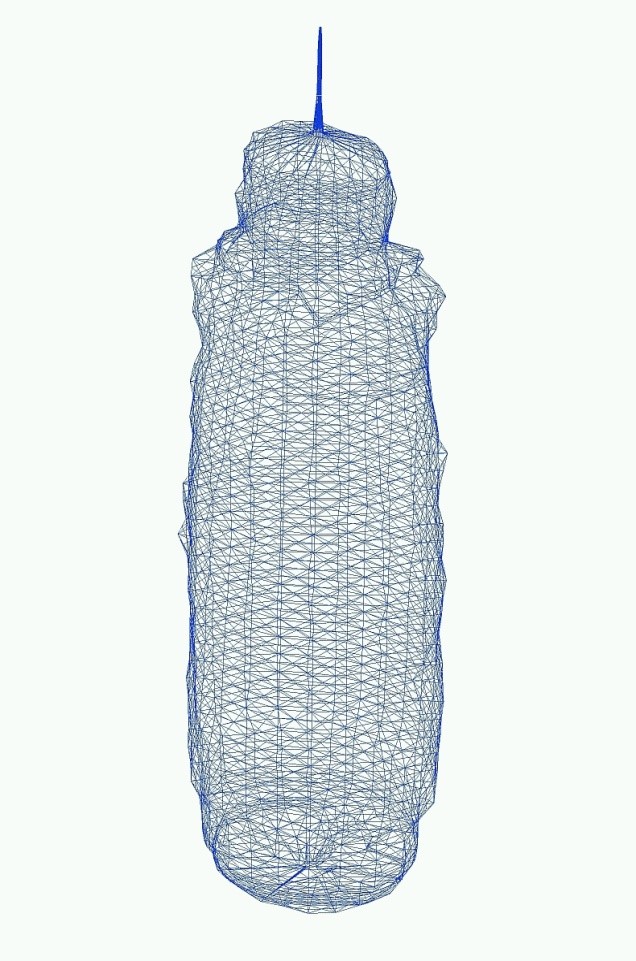

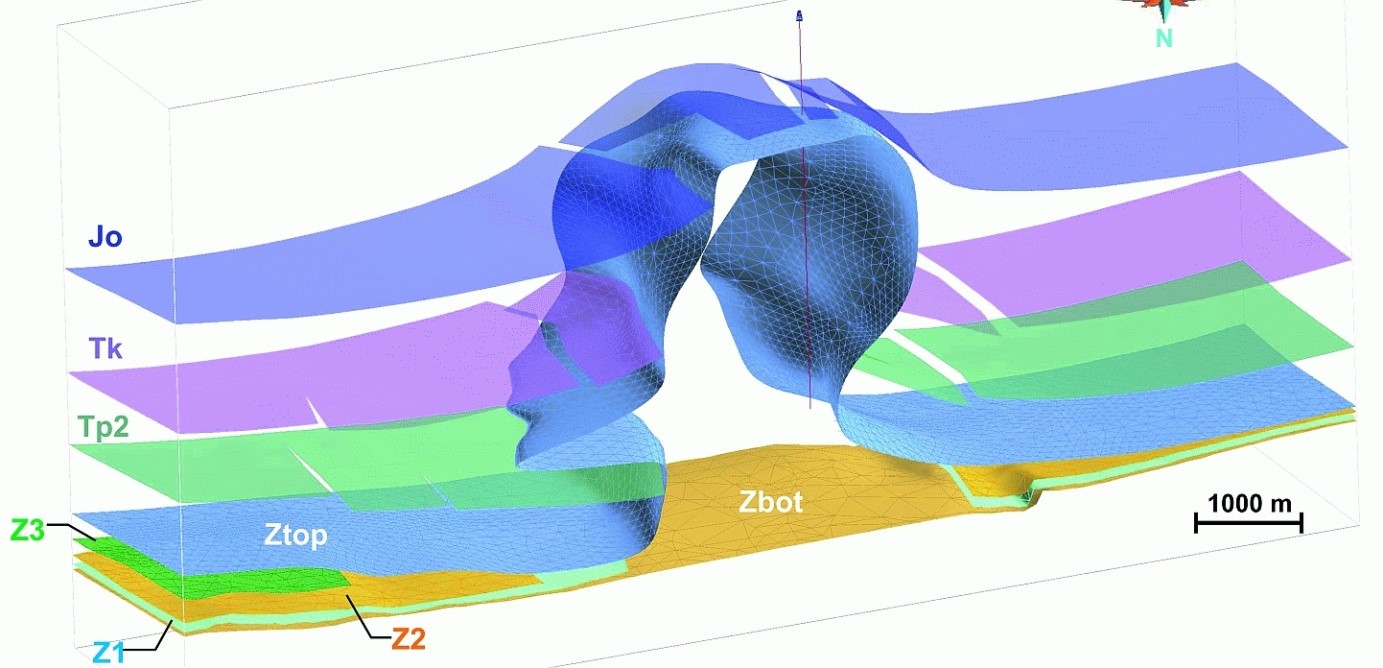

3D geological modelling

Source: GSP

We have long experience in working with best computer tools (GOCAD Paradigm, Surfer, ArcView Arc GIS, Win Ubro, Auto Cad) for:

Source: GSP

We have long experience in working with best computer tools (GOCAD Paradigm, Surfer, ArcView Arc GIS, Win Ubro, Auto Cad) for:

- geological maps and sections,

- 3D geological modelling (visualisation of the geology with various objects),

- integration of all relevant geological, geophysical and other data in 3D environment,

- generation of geological maps and sections in selected directions, based on 3D models,

- creation of geological, geophysical and mining data bases,

- creation of GIS data bases,

- calculation of deposit reserves,

- geostatic analysis of reservoir parameters,

- identification of reservoir parts suitable for the development of underground gas storage facilities (CUGS).

Source: GSP

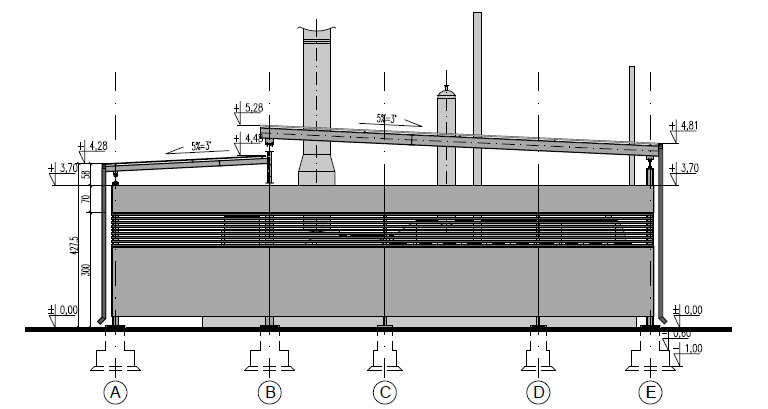

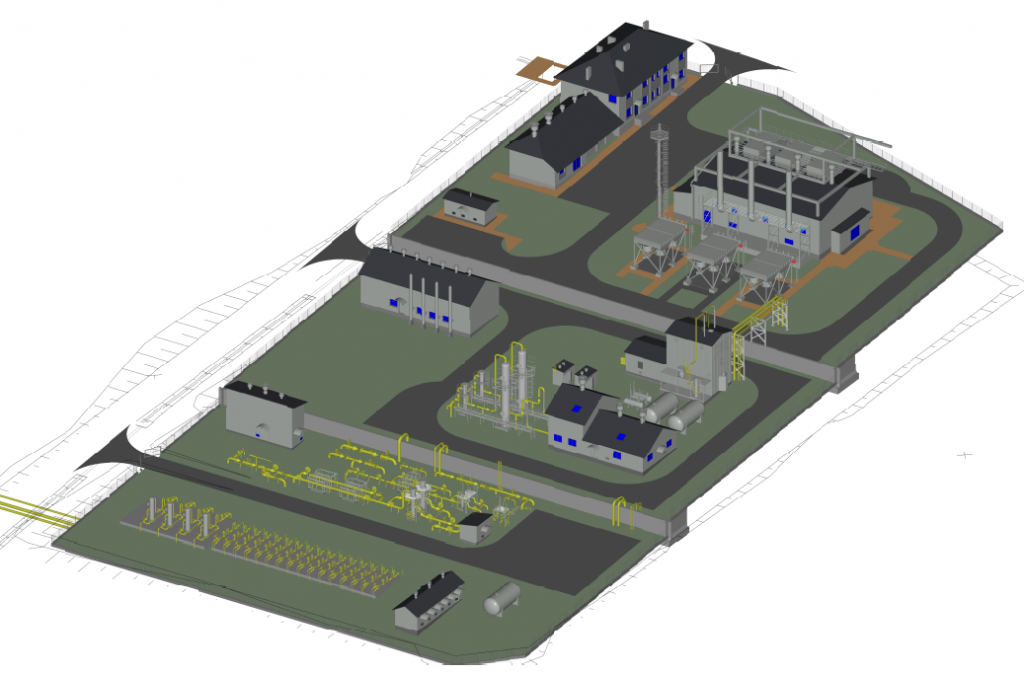

Source: GSPSurface Works

Design

Source: GSP

Source: GSP

The delivery of the engineering design of the surface part comprises the entire UGS infrastructure serving for the storage cavern construction and, subsequently, their operation as gas storage holders. The principal elements of the surface installation include:

- equipment used for the leaching storage caverns (pumps, water and brine pipelines, blanket medium, equipment controlling solution mining pipes, control and measurement apparatus),

- equipment for gas compression, transmission and dehydration and control and measurement equipment,

- power lines, buildings, access road.

Supervision and commissioning

Source: GK PGNiG

Source: GK PGNiG

Completed projects

CUGS Mogilno

The contribution of our employees to the CUGS Mogilno project

Our specialists gained considerable experience during the construction and operation of CUGS Mogilno, taking part in activities related to:

- project preparation: licensing, feasibility study together with the analysis of technical and economic conditions,

- formal and legal procedures in the process of project preparation,

- supervision over the construction of surface and underground facilities,

- detailed engineering design of the subsurface part,

- construction of the subsurface infrastructure – wells, solution mining, completion and first gas injection,

- commissioning,

- operation.

Source: GK PGNiG

Source: GK PGNiG

The construction of CUGS Mogilno

The construction of CUGS Mogilno involved conforming to a number of formal requirements, preparing the documentation and obtaining the necessary decisions, including:

- initial investment assumptions,

- licence,

- feasibility study: project definition and characteristics, feasibility, financial, economic and risk analyses,

- formal and legal documents related to the introduction to the local development plan,

- approval of the engineering and process documentation, building permit design, issuance of the building permit.

It was also necessary to prepare engineering and process documentation which required specialist knowledge and comprised, inter alia:

- deposit development plan,

- geological documentation,

- operations plan,

- engineering design,

- manuals.

It was necessary to develop the documentation concerning the well drilling technology, which required drilling expertise and included, inter alia:

- geological and technical assumptions,

- scope of analyses and tests,

- cementation of pipes and tubing,

- sample collection, coring.

In addition, specialist documentation, which required the understanding of cavern construction technology was necessary, including

- physiochemical salt analyses,

- determination of the cavern base interval, as well as geometry and storage pressure design,

- installation for cavern construction (parameters),

- leaching, brine disposal,

- technological survey while leaching.

The operation of CUGS Mogilno

The specific considerations in the operation of a storage facility which fulfils a regulating role within the storage system:

- significant variations of the rates of gas withdrawal from and injection to the storage facility,

- facility operation modes switched independently to the winter and summer season,

- possibility to withdraw gas from the UGS facility at the rate of 860 thousand m3/h in the direction of the Gustorzyn network point,

- maximum rate of gas injection to the UGS facility up to 400 thousand m3/h (enables full injection of the facility within 54 days).

Operating modes of CUGS Mogilno:

- injection without compressors,

- injection with compressors,

- withdrawal without compressors,

- withdrawal with turbo compressors,

- first gas injection with brine withdrawal.

Expansion

The expansion will enable, among other things:

- increased share of the working volume in the annual gas consumption,

- improved security of gas supply through the development of additional working volume located at convenient points within the transmission system,

- optimisation of long-term contracts,

- optimisation of procurement management,

- ultimately, this will enable the extension of the storage service portfolio onto such services as “parking”, “loaning”, “banking” and others, available in markets with significant natural gas storage capacity.

The scope of work involved in the expansion of the surface part:

- expansion of the solution mining installation,

- construction of upstream and methanol pipelines,

- construction of process trains at the gas distribution station,

- expansion of the methanol compressor station,

- upgrade of the control and protection system,

- development of areas adjacent to the wells.

The scope of work involved in the expansion of the subsurface part:

- drilling,

- well completion for solution mining,

- solution mining of storage cavities,

- well completion for first gas injection into to the cavern,

- first gas injection to caverns,

- removal of brine pipes,

- installation of downhole safety valve.

CUGS Kosakowo

Source: GK PGNiG

Source: GK PGNiG

Source: GSP

Source: GSP

The contribution of our employees to the CUGS Kosakowo project

Our specialists have been accumulating considerable experience during the construction of CUGS Kosakowo, taking part in activities related to:

- project preparation: licensing, feasibility study together with the analysis of technical and economic conditions,

- management of formal and legal procedure in the course of project preparation, obtaining necessary decisions and permits,

- supervision over the construction of surface (including specifically the solution mining and gas plant) and underground facilities,

- detailed engineering design of the subsurface part,

- construction of the subsurface infrastructure – wells, solution mining, completion and first gas injection,

- commissioning.

Leaching with the use of nitrogen blanket

Directional well drilling to storage caverns:

- this technology proves particularly useful at places where reservoir accessibility is significantly constrained by surface conditions,

- 15 m distance between well outlets on the surface,

- S-type directional well.

The disposed brine is diluted in the waters of the Bay of Puck by the means of a diffuser system:

- brine discharge through a DN300 pipeline deep into the Bay of Puck;

- the quantity of discharged brine will amount to max. 300 m3/hour with average saturation of 250 kg/m3;

- the pipeline ends with a diffuser installation positioned at the distance of 2.3 km from the coastline, in a region where the Bay is 8 m deep;

- a diffuser system will ensure that the salt saturation level around the point of brine discharge will not increase by more than 0.5 psu comparing to the current baseline level for the Bay of Puck.

UGS Strachocina

Our specialists were in charge of the expansion of the surface part of the facility, acting in the capacity of the Lead Contractor within a consortium set up by three subsidiaries of the PGNiG Group.

Objective: capacity increase (from 150 to 330 million cu.m) in the existing Underground Gas Storage facility in a natural, depleted gas field

The project involved:

- extensive drilling,

- modernisation of existing surface infrastructure,

- construction of new installations.

Source: GSP

Source: GSP

Chemkop - research and development

Research and development activities:

- analyses of physiochemical, mechanical and rheological properties of halites,

- analyses of solution mining properties of halites,

- extensive research on the impact of UGS construction and operation on the environment,

- storage cavern convergence,

- land surface movements,

- subsurface stability,

- integrity tests of storage facilities during operation,

- cement bond logging of wells,

- ... and many others.

GSP is the majority shareholder of Chemkop (Research and Development Centre for Chemicals Extraction Industry) in Krakow.

Chemkop – business profile

The company specialises in research studies and engineering, as well as related services for the purposes of underground storage and wellbore and underground extraction, including specifically:

- salt mining and solution mining,

- development of underground storage facilities for gas and liquid hydrocarbons in salt caverns,

- echometric cavern surveys,

- specialist computer applications,

- geology, hydrogeology and geotechnics,

- environmental issues, including:

- safe disposal of waste,

- removal of groundwater and surface water contamination,

- environmental chlorine production facilities,

- metrology.

In accordance with the above scope, end-to-end services are provided at the stage of initial studies and concept development, research, assessment of technical and economic feasibility and conditions, design, technology transfer as well as the supervision of construction and commissioning.

To date, the cooperation concerned the following areas:

- general engineer of CUGS Mogilno,

- tests and measurements of cavern geometry by the means of an echo sounder and computer modelling based on the measurement data,

- software application for engineering and simulation of solution mining process (WinUbroNET),

- laboratory tests of evaporate rock samples,

- shale gas – production technology.

The scope of joint activities covers, inter alia, research studies and engineering, as well as related services for the purposes of underground storage disposal and wellbore and underground extraction. This includes comprehensive support in the following areas:

- study and concept development phase,

- research studies,

- assessment of technical and economic options and conditions,

- design, technology transfer,

- supervision of construction and commissioning.

The most important benefits of the cooperation include:

- consolidation of knowledge, experience and equipment and minimisation of the cost for foreign business partners,

- exchange of experience in the area of engineering, construction and operation of UGS facilities in salt caverns and salt dome wells,

- access to proprietary CHEMKOP's technologies from the above-mentioned areas,

- access to CHEMKOP's databases for study and analysis purposes,

- an important link in the value chain remains within the PGNiG Group.