Gromadź piękne chwile. My zajmiemy się gazem.

-

12.04.2024

Informacja o zmianie charakterystyk zatłaczania i odbioru dla GIM Kawerna od początku sezonu 2024/2025

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu pełniąca →

-

05.04.2024

Zaproszenie do udziału w badaniu zapotrzebowania na usługi magazynowania paliwa gazowego

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu („GSP") →

-

26.03.2024

Informacja dotycząca parametrów Zdolności Magazynowych na Warunkach Ciągłych udostępnionych zgodnie z ogłoszeniem z dnia 29.01.2024 r. w Instalacji Magazynowej PMG Wierzchowice, w GIM Kawerna oraz w GIM Sanok oraz możliwości świadczenia do 30.09.2024 r. części Zdolności Magazynowych na Warunkach Przerywanych jak Zdolności Magazynowych na Warunkach Ciągłych.

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu, wyznaczona →

-

29.01.2024

Informacja o udostępnieniu Zdolności Magazynowych w Instalacji Magazynowej PMG Wierzchowice, w GIM Kawerna oraz w GIM Sanok

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu, wyznaczona →

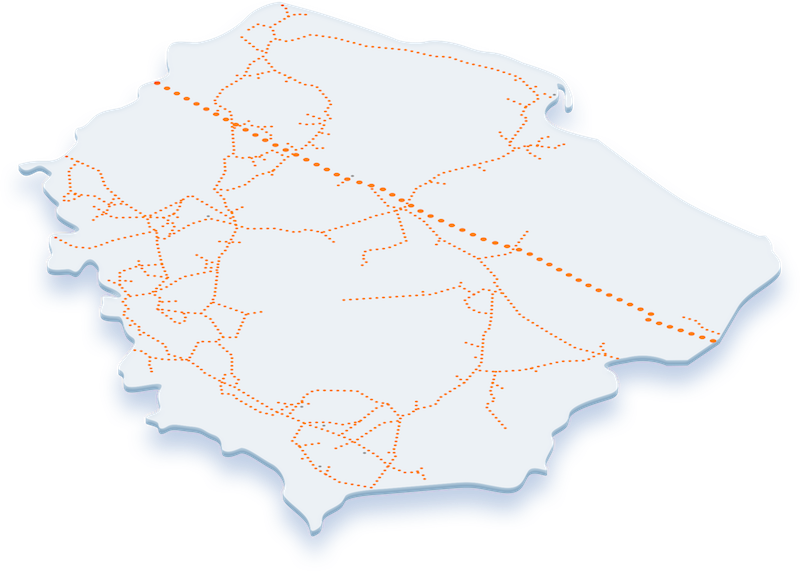

Lokalizacje PMG

GIM Kawerna

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

GIM Kawerna

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

IM Wierzchowice

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

ilość gazu odebranego

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu zatłoczonego

Stan napełnienia instalacji magazynowych

Dane na koniec doby gazowej 26.04

(stan na godzinę 6:00)*

*) dane te są równoważne z danymi na początek następnej doby gazowej

Gromadź piękne chwile. My zajmiemy się gazem.

Stan napełnienia instalacji magazynowych

Dane na koniec doby gazowej 26.04

(stan na godzinę 6:00)*

*) dane te są równoważne z danymi na początek następnej doby gazowej

Gromadź piękne chwile. My zajmiemy się gazem.

-

12.04.2024

Informacja o zmianie charakterystyk zatłaczania i odbioru dla GIM Kawerna od początku sezonu 2024/2025

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu pełniąca →

-

05.04.2024

Zaproszenie do udziału w badaniu zapotrzebowania na usługi magazynowania paliwa gazowego

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu („GSP") →

-

26.03.2024

Informacja dotycząca parametrów Zdolności Magazynowych na Warunkach Ciągłych udostępnionych zgodnie z ogłoszeniem z dnia 29.01.2024 r. w Instalacji Magazynowej PMG Wierzchowice, w GIM Kawerna oraz w GIM Sanok oraz możliwości świadczenia do 30.09.2024 r. części Zdolności Magazynowych na Warunkach Przerywanych jak Zdolności Magazynowych na Warunkach Ciągłych.

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu, wyznaczona →

-

29.01.2024

Informacja o udostępnieniu Zdolności Magazynowych w Instalacji Magazynowej PMG Wierzchowice, w GIM Kawerna oraz w GIM Sanok

Gas Storage Poland sp. z o. o. z siedzibą w Dębogórzu, wyznaczona →

Gromadź piękne chwile. My zajmiemy się gazem.

Gromadź piękne chwile. My zajmiemy się gazem.

Lokalizacje PMG

GIM Kawerna

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego

GIM Kawerna

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego

IM Wierzchowice

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego

GIM Sanok

Stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na początek doby

stan napełnienia instalacji magazynowych na koniec doby

ilość gazu odebranego

ilość gazu zatłoczonego